Kobet Chainsaw Chain: Full Industrial Chain Precision Manufacturing, Defining the New Benchmark in Cutting Performance

Kobet Chainsaw Chain consistently upholds the core principle of “Forging Durable and Reliable Cutting Tools.” Leveraging a complete in-house production line encompassing Stamping, High-Frequency Heat Treatment, Cold Rolling, Sharpening, and Assembly, we transform meticulous control over each process step into the product’s core competitive strength, delivering stable and efficient cutting performance to global users.

Full-Process Production Line: Forging Product Excellence

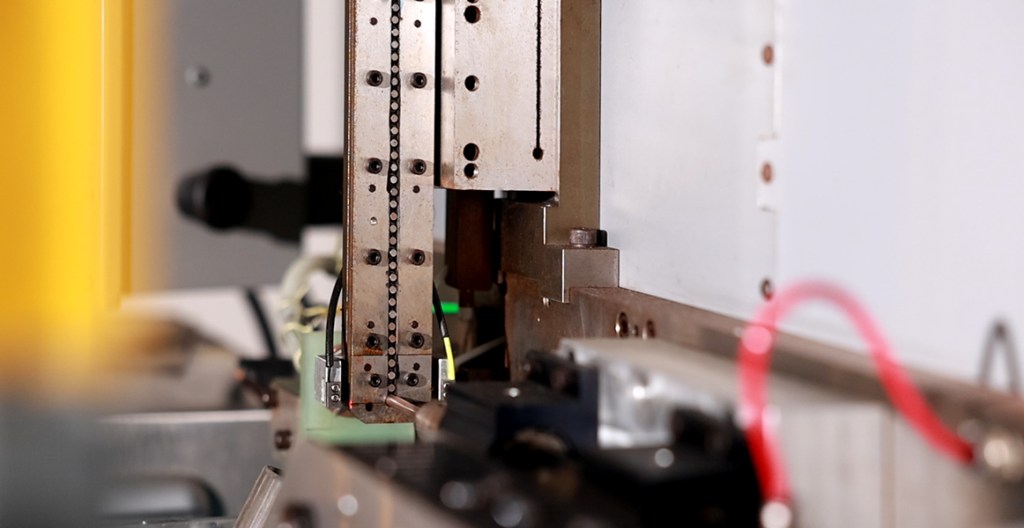

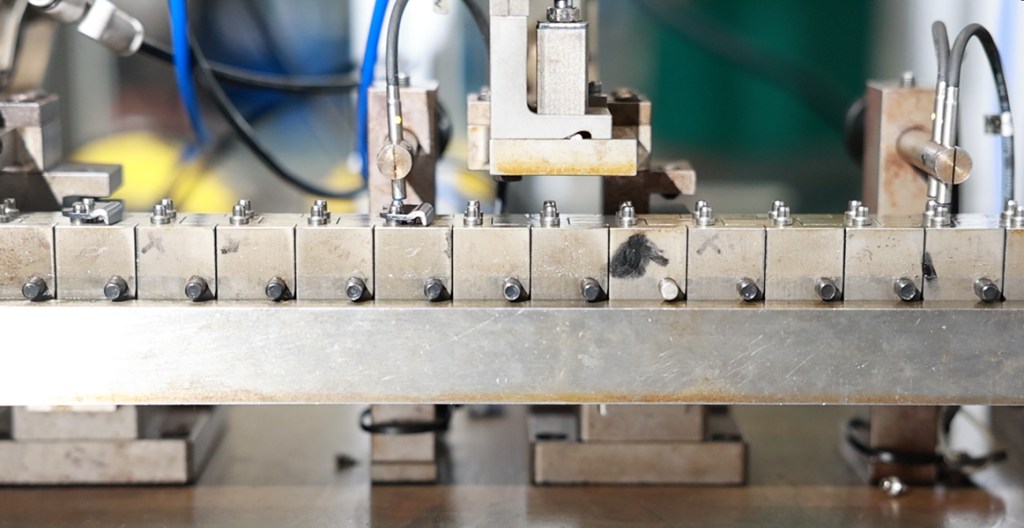

Precision Stamping: Accurate Forming, Laying the Structural Foundation

Kobet utilizes high-precision stamping lines. Customized dies precisely stamp premium steel, ensuring dimensional tolerances for core components like drive links, tie straps, and rivets are controlled within 0.02mm. This guarantees perfect alignment of connection holes and cutter profiles with design specifications. Stable stamping not only ensures fundamental structural integrity but also minimizes fitment errors in subsequent assembly, laying a solid foundation for overall product stability.

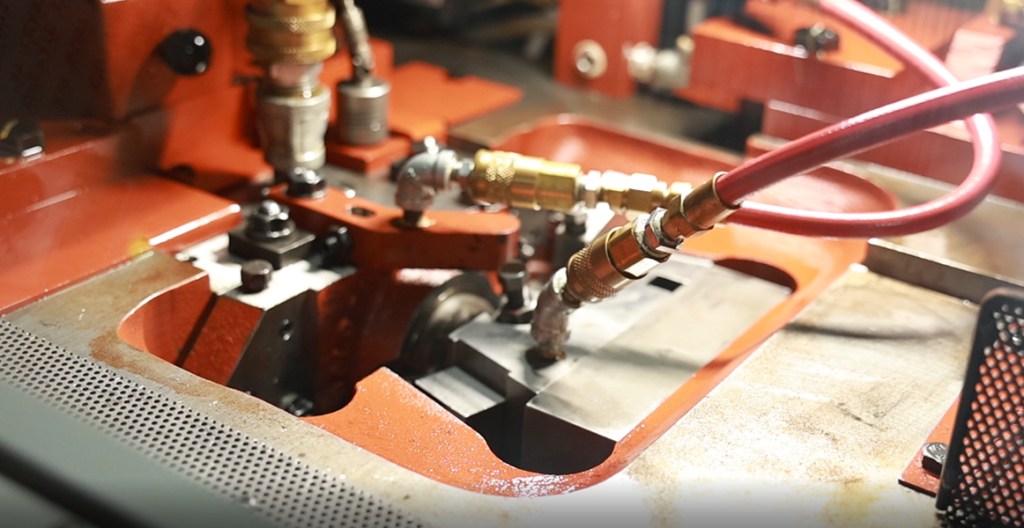

High-Frequency Heat Treatment: Material Strengthening, Enhanced Wear Resistance

The High-Frequency Heat Treatment line is Kobot’s “key advantage” for chain durability. Using high-frequency current, critical load-bearing areas of the chain are locally heated and rapidly quenched. This forms a uniform hardened layer on the cutter surface, achieving hardness of HRC58-62, while the core retains excellent toughness. This “hard surface, tough core” characteristic enables the chain to withstand intense friction during high-speed wood cutting while absorbing impact loads, significantly reducing the risk of breakage or cutter damage. Service life is extended by over 30% compared to standard chains.

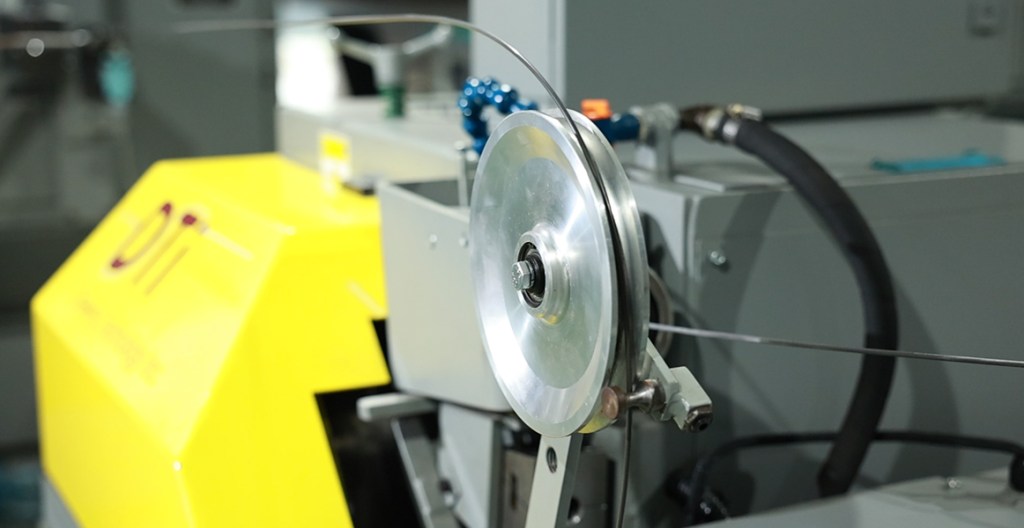

Cold Rolling Process: Optimized Precision, Ensuring Smooth Operation

The Cold Rolling line processes components like rollers and bushings using multi-stage rollers in a cold state. Without compromising the internal material structure, this controls roundness error within 0.01mm and reduces surface roughness to below Ra0.8. Cold-rolled components provide more uniform contact area and tighter clearances during chain operation. This effectively reduces vibration and noise, resulting in smoother cutting and reduced operator fatigu.

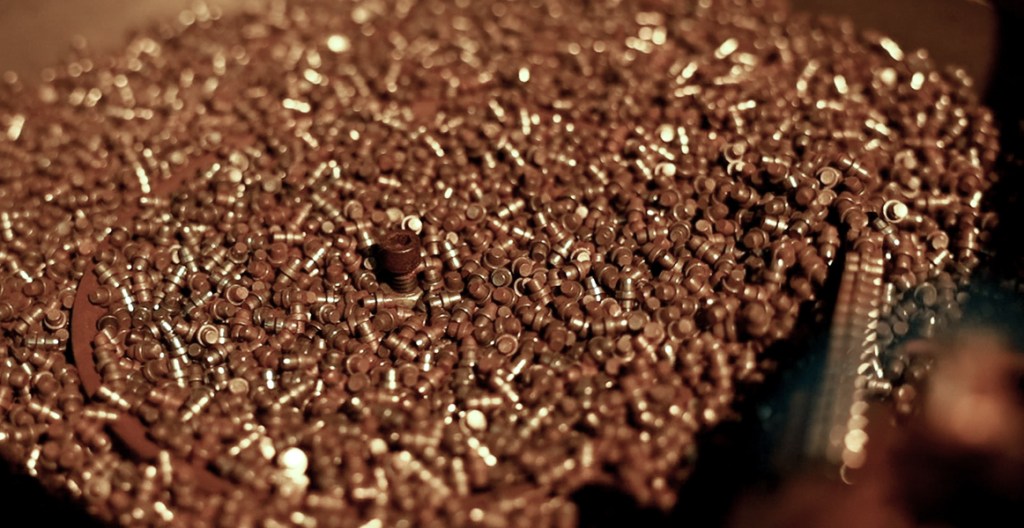

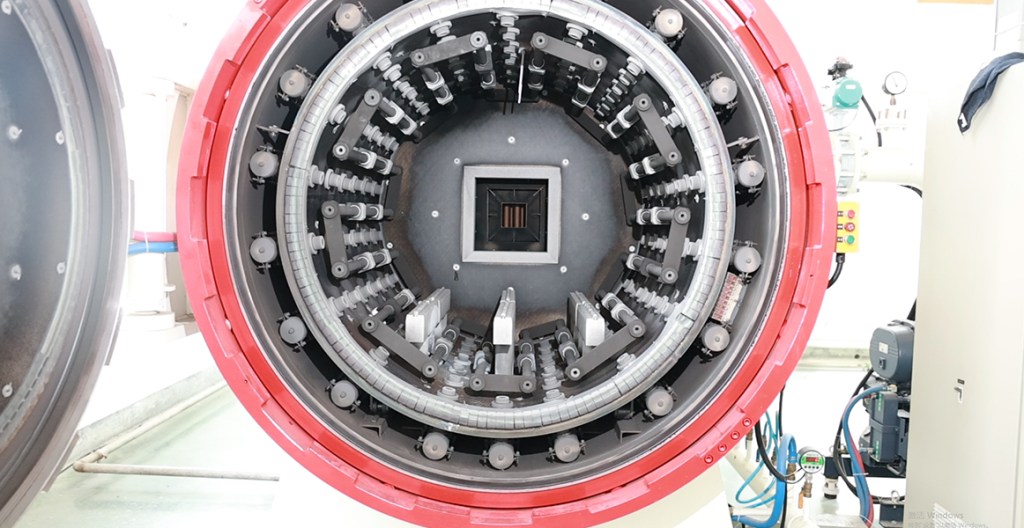

Precision Sharpening: Honing the Edge, Boosting Cutting Efficiency

Kobet’s fully automated sharpening line employs CNC technology for precise grinding based on specific chain model cutter geometry parameters (e.g., top plate cutting angle, side plate clearance angle, corner radius). Grinding accuracy reaches 0.05mm, ensuring every cutter is uniformly sharp with consistent angles. This enables easier wood penetration, produces cleaner cuts, and increases work efficiency by over 20%, particularly beneficial for hardwoods or frozen wood.

It is noteworthy that Kobet maintains stringent control over heat treatment processes throughout the entire production cycle.

Beyond High-Frequency Heat Treatment, the chain undergoes comprehensive tempering via a multi-stage, temperature-controlled overall heat treatment process. This technique further refines the internal grain structure of the chain material, resulting in a more homogeneous microstructure. Consequently, the overall mechanical properties of the chain are enhanced, enabling it to maintain structural stability under repeated impacts and sustained loads. This fundamentally precludes localized failures caused by material inhomogeneity, adding another robust layer of assurance to the chain’s longevity and durability.

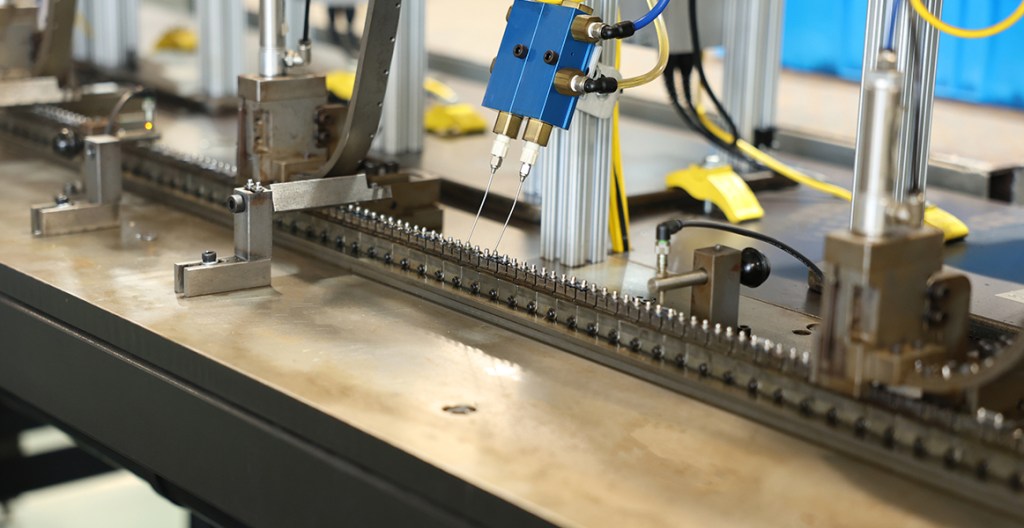

Intelligent Assembly: Precision Fitment, Guaranteeing Overall Performance

During assembly, Kobet employs automated lines where robotic arms and sensors ensure precise alignment of drive links, tie straps, rivets, rollers, and bushings. Equipment continuously monitors critical parameters like pitch accuracy and flexibility in real-time, rejecting non-conforming products. Chains assembled under this strict regimen operate smoothly at high speeds without binding or loosening. They perfectly adapt to guide bars from various chainsaw brands, ensuring efficient, lossless power transmission.

From raw steel to finished product, Kobet establishes a comprehensive quality control system through its complete production line. Each chainsaw chain embodies the precision of stamping, the toughness of high-frequency treatment, the exactness of cold rolling, the sharpness of grinding, and the rigor of assembly – ultimately becoming a cutting tool renowned for durability, efficiency, and compatibility. Choosing Kobet means choosing professional quality proven in the most demanding conditions.