Kobet: Dedicated to Harvest Guide Bars, Forging Excellence with Automated Precision Craftsmanship

In the realm of chainsaw chains and harvest guide bars, Kobet steadfastly upholds ultimate professionalism and leads the industry with fully automated production. We focus intensely on the R&D and manufacturing of harvest guide bars. Through relentless pursuit of quality and masterful fully automated processes, we have earned deep trust and recognition from our customers.

Every Kobet harvest guide bar undergoes 12 rigorous fully automated processes, with intelligent control from raw material to finished product, delivering only the highest quality.

Raw Material Inspection:

Automated smart detection equipment conducts comprehensive composition and performance scanning of raw materials, precisely rejecting non-conforming inputs. Automation fortifies quality foundations.

Laser Cutting / Waterjet Cutting:

Fully automated intelligent cutting systems execute cutting commands via preset programs with micron-level precision, ensuring perfect dimensional and geometric conformity to design specifications for diverse working conditions.Heat Treatment: Fully automated intelligent temperature-controlled heat treatment lines monitor and adjust temperature and duration in real-time. This enables precise control of bar hardness, strength, and wear resistance, significantly extending service life.

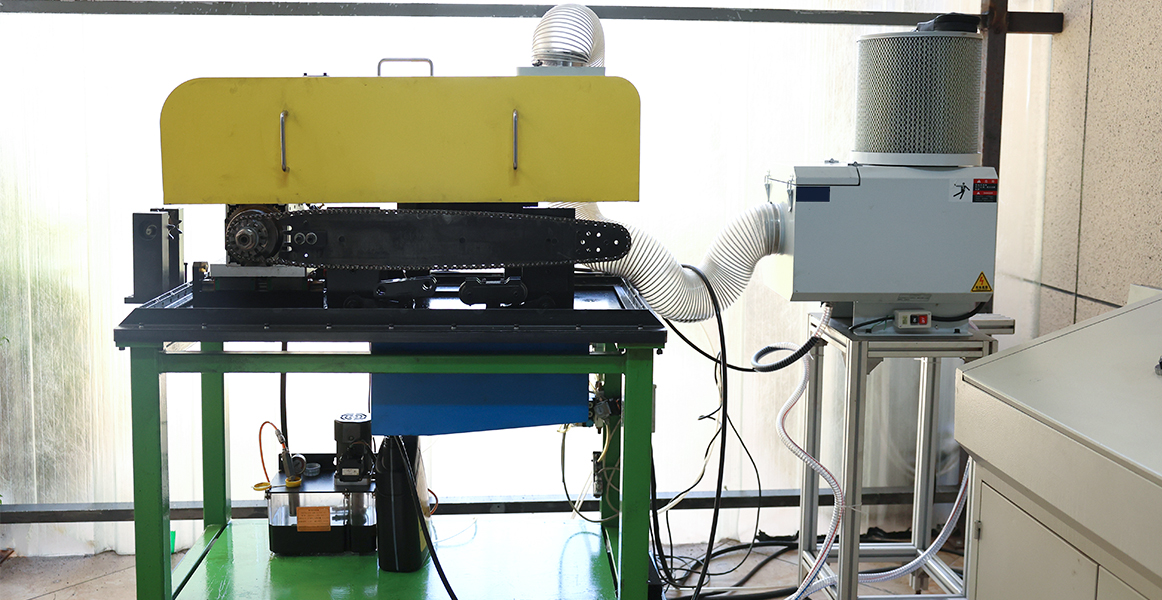

Polishing:

Automated continuous polishing lines utilize robotic arms operating along preset paths to efficiently remove surface burrs and imperfections. Achieves mirror-level surface smoothness, markedly reducing operational friction.

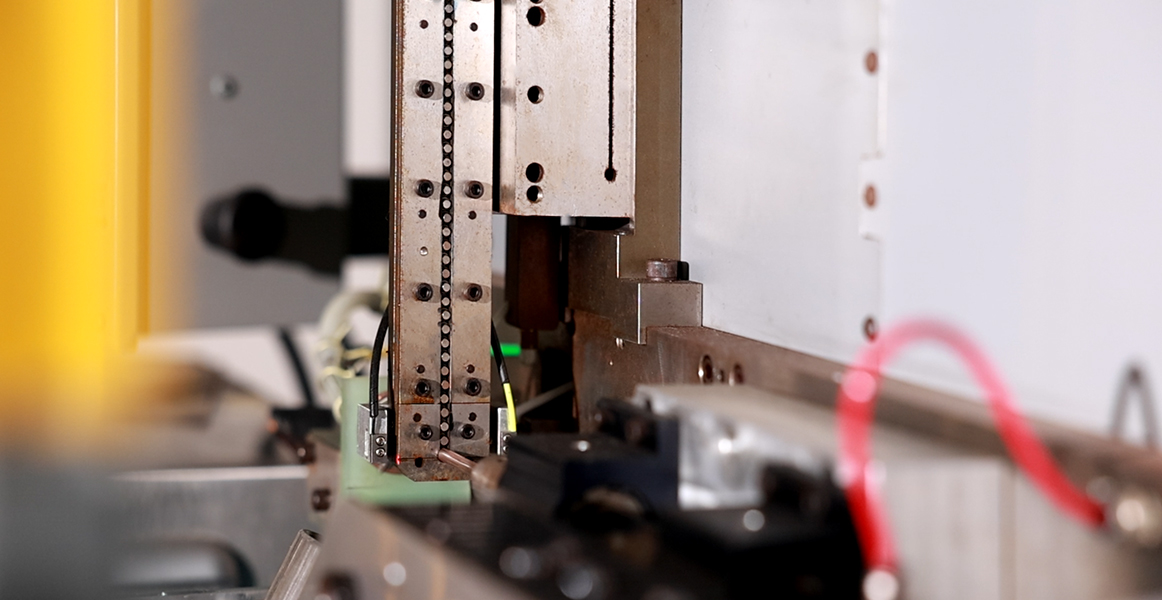

Milling the Bar Groove:

Fully automated precision milling equipment processes grooves programmatically. Constant cutting force and speed guarantee dimensional accuracy and surface finish, ensuring smooth chain operation.

Milling the Bar Nose: Automated milling units operate with parametric precision, shaping the nose to exact design standards. Enhances compatibility with chainsaws and operational stability, eliminating manual error.

Drilling Oil Holes: Fully automated CNC drilling machines create holes at preset coordinates with minimal positional deviation. Ensures efficient lubrication delivery to the chain/bar interface, effectively reducing wear.

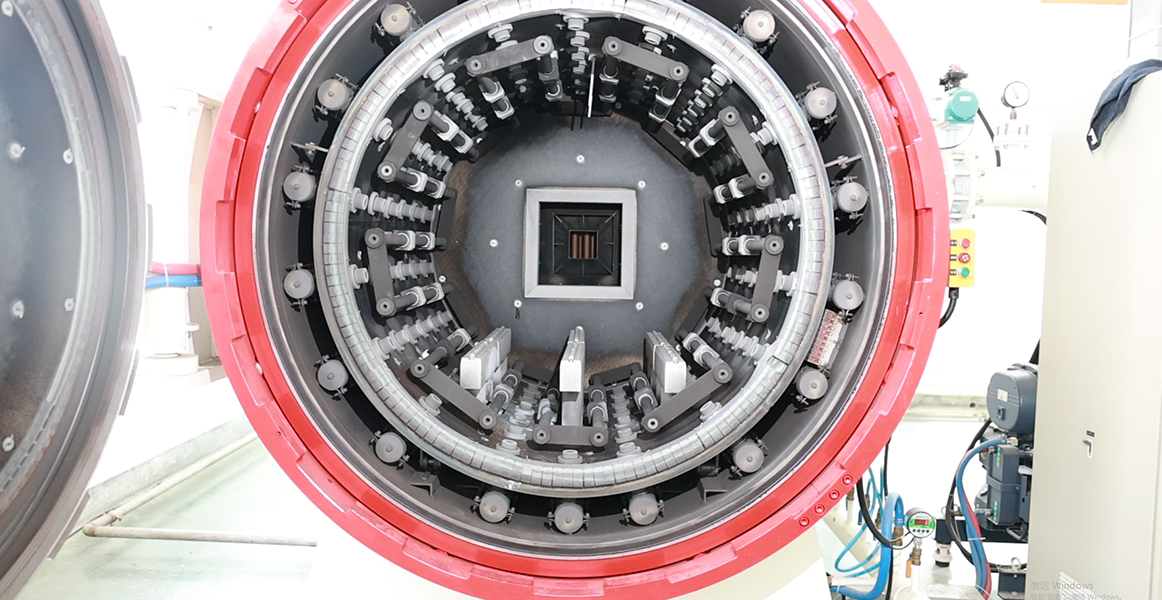

Laser Heat Treatment / High-Frequency Treatment: Automated positioning systems guide lasers or high-frequency equipment to precisely strengthen critical bar areas. Further enhances durability and fatigue resistance, ensuring operational safety.

Sealing Process Holes:

Automated repair robotic arms accurately identify and seal process holes, guaranteeing structural integrity and sealing consistency, eliminating manual repair variability.

Surface Grinding/Finishing:

Secondary surface finishing is performed by fully automated high-precision grinding equipment. Intelligent pressure control achieves industry-leading flatness, improving operational stability and safety.

Final Inspection: Fully automated quality control lines conduct multi-dimensional inspections (dimensions, hardness, surface quality) on every bar. Data is uploaded in real-time; non-conforming products are automatically diverted, ensuring 100% compliance before shipment.

Packaging & Shipping:

Automated packaging robotic arms pack products rapidly according to specifications. Integrated with intelligent warehousing and logistics systems, this ensures efficient dispatch and intact product delivery.

Kobet: Defining Professionalism through Automation, Building Trust with Intelligent Craftsmanship.

We remain dedicated to harvest guide bar production, continuously advancing our processes through our fully automated production system. We deliver more professional, reliable, and efficient products to enhance your productivity and operational efficiency.

Choose Kobet. Choose the Professionalism and Assurance of the Automation Era.