In the field of chainsaw chains and Guide bars, Kobet consistently upholds an uncompromising pursuit of quality. Leveraging robust production capabilities and advanced technological advantages, we provide global users with high-performance, durable chainsaw guide bar and chain products.

Solid Strength, Rooted in Expansive Infrastructure

Kobet operates a modern production base spanning 8,000 square meters. The spacious, well-lit workshops and scientifically optimized layout form a solid foundation for the scaled and efficient production of chainsaw guide bars and chains. This extensive facility accommodates a large number of advanced production machines while providing ample space for raw material storage, product processing, finished goods inspection, and warehousing. This ensures smooth, highly efficient production workflows, enabling us to reliably meet high-volume orders from diverse customers and guarantee timely product supply.

Cutting-Edge Technology, Forging Superior Quality

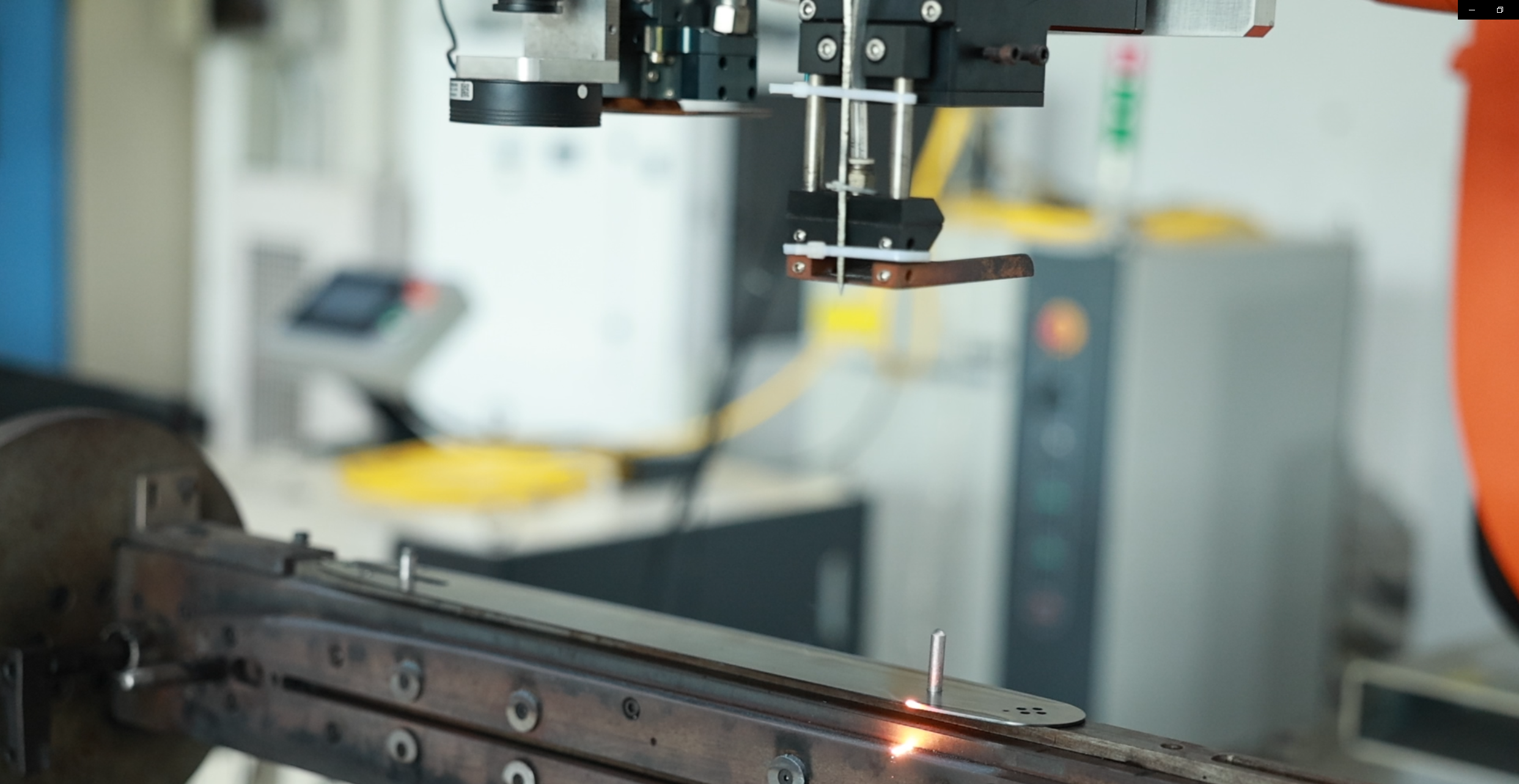

Laser Technology: Precision Detailing

Kobet employs advanced laser cutting technology in the machining process of chainsaw guide bars. Laser cutting delivers exceptional precision, enabling the accurate cutting of guide bars to exact design specifications, with minimal tolerance deviations. This ensures a tighter fit between the chain’s drive links and the guide bar, reducing friction during operation, minimizing energy loss, and enhancing cutting efficiency. Furthermore, the laser’s minimal heat-affected zone preserves the structural integrity of the guide bar material, ensuring chain strength and toughness for extended service life.

Waterjet Technology: Handling Complex Processing Needs

Complementing laser technology, Kobet utilizes advanced waterjet cutting equipment. Waterjet technology employs a high-pressure stream of water mixed with abrasive garnet to cut materials. It excels at handling intricate shapes and complex cutting requirements, particularly for irregular structural components on chainsaw chains. As the cutting process generates no heat, it prevents material deformation and oxidation, ensuring dimensional accuracy and performance stability of the guide bars. Waterjet technology precisely processes both thick and thin guide bars, providing robust support for diversified product designs.

Choosing Kobet chainsaw guide bars and chains means choosing quality and assurance. Backed by formidable production strength and driven by core technologies like advanced laser and waterjet cutting, we continuously elevate product quality. We are committed to providing you with more efficient, longer-lasting chainsaw chain products, empowering your work with greater productivity.